How to use drag chain? How to use drag chain

The service life of a drag chain is affected by a number of data, including technical indicators such as load weight, moving distance, and moving speed. It is also affected by the use environment, such as ambient temperature, dirt, and impact force. Therefore, unreasonable and incorrect use of the drag chain will Will greatly reduce its lifespan!

Regarding the current widespread use of drag chains and the installation of various types of drag chains, we will make the following simple instructions to teach you how to use drag chains, as well as the installation location and operation of drag chains on equipment;

How to use drag chain

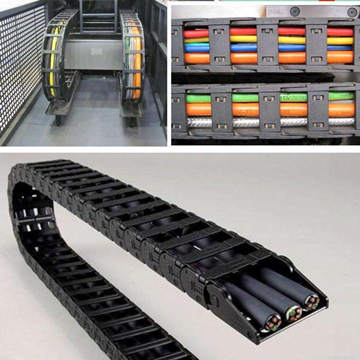

The drag chain is the most basic cable protection accessory. It can effectively protect cables and oil pipes, and can run back and forth with the equipment. Its use can be said to be very simple. Just pass the cable through it and it can be used. Of course, for some things that cannot be used For the cables that are passing through or the cables that have been fixed, we can open the Minbin drag chain crossbars for laying lines, and then assemble them and install them.

Where does the power of the drag chain come from?

Whether it is a steel drag chain or a nylon drag chain, it does not generate power by itself. Its power is tensile force, which is generated after the equipment is driven, and is not a force generated by itself.

What are the mobile and fixed ends of drag chains?

Both ends of the drag chain are equipped with joints with mounting holes, also called connectors. The moving end of the drag chain is connected to the machine head or the moving end, which is called the moving end joint. The fixed end is fixed on a prior The set position does not move and does not produce any pulling force or any power. It is called a fixed end joint.

The installation position of the drag chain is crucial

The installation of drag chain is a simple and careful work, because the installation of Minbin drag chain is closely related to the later service life of the drag chain. For example, we will not install the moving end and fixed end of a drag chain on the same parallel line. , then the drag chain will produce resistance when traveling, and each chain link will be very difficult to rotate. This will increase the wear and tear of the drag chain itself.

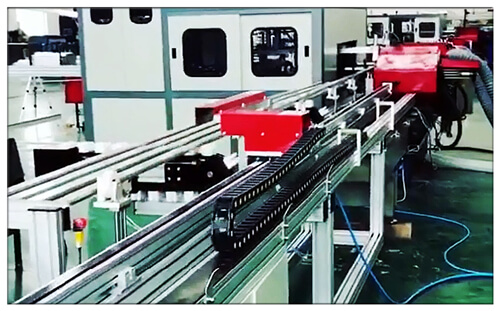

The use of drag chains in linear modules seems simple, but in fact there are many considerations.

Don’t forget to reserve space for the drag chain when evaluating the use plan

For many new engineers, the overall equipment design space is very compact, and they underestimate the space of the drag chain. When the assembly personnel come to find you, it is really a painful realization.

2. Pay attention to the usage environment.

Linear module drag chains have different applicable environments. Some conditions are not suitable for ordinary drag chains, such as dust-free, anti-static, silent, wear-resistant, waterproof, oil-proof, debris-proof, etc., so pay attention to the use environment. important.

3. Minimum bending radius of the cable’s trachea

Before choosing a linear module drag chain, you must know the minimum bending radius of the cable and air pipe. Otherwise, it is easy to choose a drag chain with an inappropriate bending radius, which will cause damage to the cable. Generally, it is >7.5 times the outer diameter of the cable.

4. Pay attention to cable tension

Pay attention to the length of the cable. The tension in the drag chain should be moderate. Too tight or too loose will easily cause wear. It is recommended to add a stress-relieving adjustment frame at the beginning and end of the drag chain.

5. Wires should be separated by partitions

A bunch of wires of different sizes inside the linear module drag chain must not be bundled together into the drag chain. Instead, they should be separated by partitions and arranged as far apart as possible. The spacing should not be less than 10% of the wire diameter.

6. The load must be calculated

Many linear modular energy chains have rated loads, the unit is kg/m. Therefore, one thing we cannot ignore is to check whether the weight of cables and air pipes exceeds the standard.

7. Do not fill the drag chain too full

The cables inside the drag chain must not be too full, and at least 15% of the space should be left for cable movement.

8. Pay attention to overhead travel

The stroke and overhead stroke of the linear module drag chain are limited, so it cannot be used casually by just operating a drag chain. Generally, major brands of drag chains have indicators regarding the overhead travel of the drag chain, so please pay attention to comply with them.