Long stroke sagging problem of steel drag chain

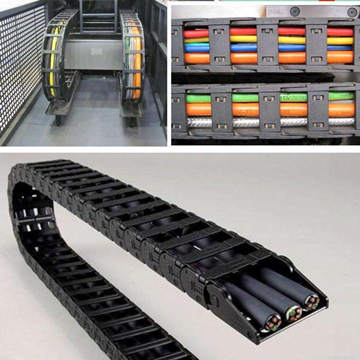

Due to the weight of the steel drag chain itself and the weight of the built-in cables, oil pipes, air pipes, and water pipes, the drag chain itself has an unsupported length limit. Drag chains of different models and materials have different unsupported length limits. If the length of the steel drag chain required exceeds this unsupported length limit, it will sag. We can solve it in the following three ways:

First, you can use guide grooves. The guide trough consists of five parts: standard length side guide wall, guide trough connecting angle steel, mounting screws, bottom trough, and sliding device. The sliding device is divided into several types of nylon wheels, steel sliding plates, and plastic sliding plates. In this way, the guide grooves are correspondingly divided into three types: guide grooves with plastic sliding plates, guide grooves with nylon wheels and guide grooves with steel sliding plates.

The second is to use support rollers. If the support wheel can be fixed on the equipment, the support wheel without a support frame can be used directly, and the drag chain rack runs back and forth on the support wheel. If the support wheel cannot be fixed on the equipment, a support wheel with a support frame can be used. The support wheel is fixed on the support frame, and the drag chain frame reciprocates on the support wheel.

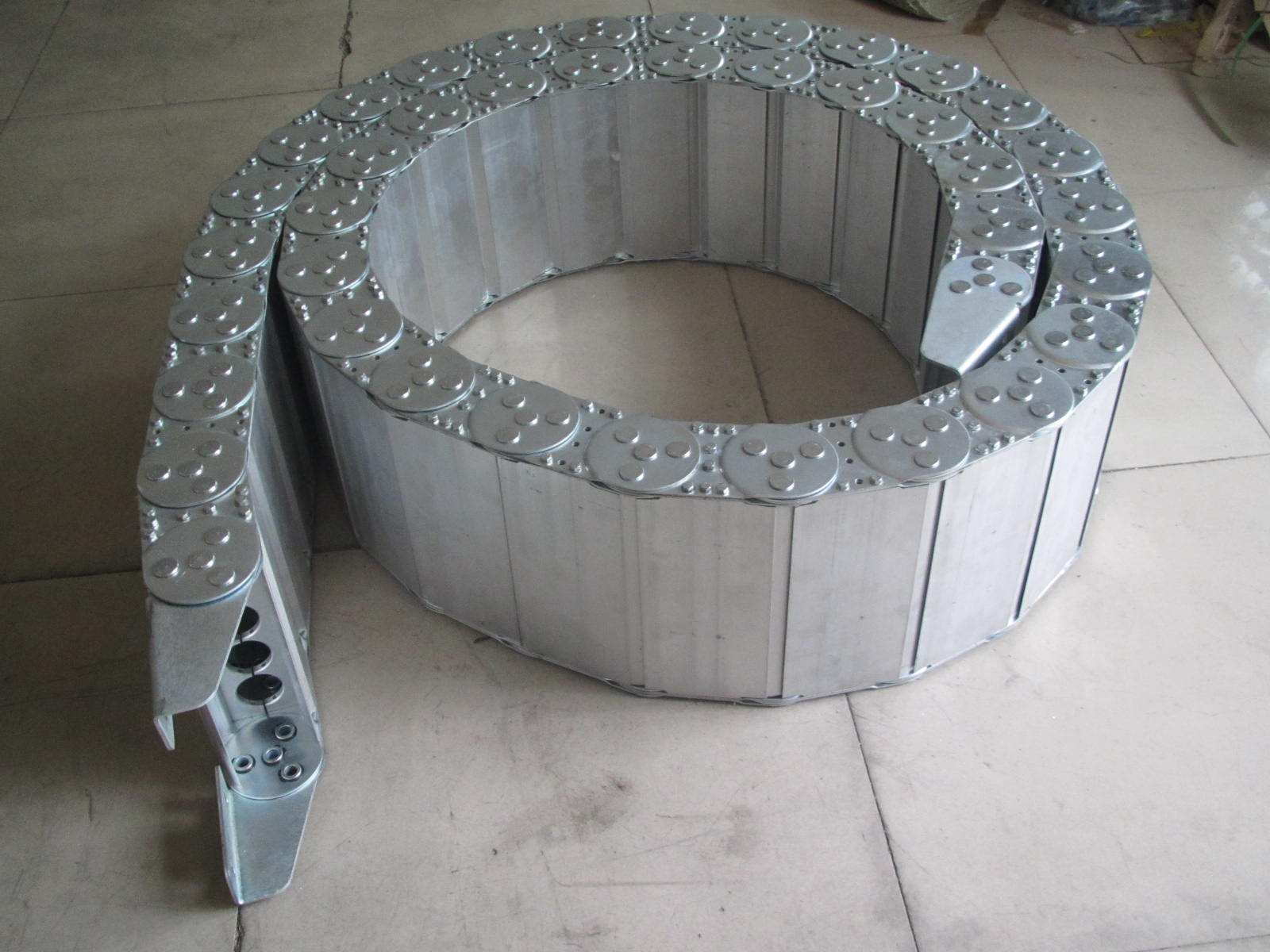

The third is to perform heat treatment and chain thickening processes on the steel drag chain links. Chain pieces can also be made of 304, 430 and other materials.

The fourth is to increase lubrication and reduce resistance, which will increase the service life of the steel drag and significantly improve the sagging phenomenon.

The fifth is to add wear-resistant blocks to make the drag chain slide smoothly, because the steel drag chain is carburized and has a strong steel function. It uses high-strength wear-resistant materials and alloy copper as the shaft pin, which improves the product's durability. It has higher wear strength, more flexible bending, smaller resistance, and reduced noise, thus ensuring that it will not deform or sag after long-term use.

To sum up, to prevent steel drag chains from sagging when running over long distances, we can use guide grooves, use support rollers, heat treat the drag chain segments, and thicken the chain segments.

Increasing the radius of the drag chain will also cause sagging. First, it is due to the weight of the drag chain. Second, the drag chain deforms as the use time increases. The best ultimate solution is to add rollers. The rollers are supported by ground connections and have side surfaces. Connect the supports.